PNTProcess

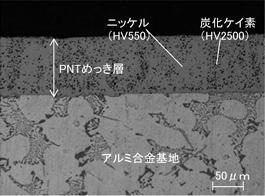

PNT plating is the compound electrolysis plating of nickel-silicon carbide improving slide performance of the aluminum alloy drastically.

- Improvement of wear resistance and galling strength for aluminum alloyed steel.

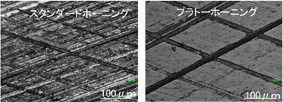

- Composite plating of Ni-SiC + Honing finishing

- PNT plating layer is composed of electro Nickel plating layer (500-600mHv) and SiC (2500mHv) dispersion particles.

- The superior wear resistance and galling strength can be obtained by lubricating oil and combination of fine super hardness SiC ceramic particles and strong plating zone.

- Assurance of higher accuracy of bore by PNT honing. For super extreme use, plateau shape is possible for oil pit.

- On the surface of parts where being high reactive surface by etching as pretreatment and melting reaction, PNT plating layer of a good adhesion can be formed.

- PNT honing is applicable to the wide range from single cylinder engine to multiple cylinder block engine.

-

PNT horning ensures high boar accuracy. The plateau horning reproduces the state just after completion of the shakedown cruise mechanically. The honing, improving the oil holding-ability in oil pit, is applied for the extreme use by the synergy with the tough film of PNT plating.

- General purpose engine, commercial engine

- For 2 wheels off-road vehicle, ATV, water jet sky, fire extinguishing pump

- Racing car engine 4 wheels vehicle

- FI, WRC, Super GT, Formula Nippon

- Racing car engine 2 wheels vehicle

- For on-road such as MOTOCROSS GP, etc., MOTOCROSS, Trial, etc.

- Cylinder for race and development

- 52,000pcs

- Block for race and development

- 3,200pcs

- Sleeve for race

- 70,000pcs

- Total production quantity

- 2,460,000pcs

Process

PNT plating layer consists of electrolytic Ni plating layer (mHV500-600) and SiC dispersion particles (mHV2500) in the layer

Record applied

Production quantity

As at the end of fiscal 2010