Gas Carburizing/Liquid Carburizing Process – ICBP

Low pressure vacuum carburizing

Process

-

Formation of high tough carburizing layer with free oxides

Quenching with less distortion by high pressure gas or oil, suiting the materials

Case depth formation ensuring the high carbon concentration layer with dispersion of fine spherical carbon

Formation of case dept carburizing layer with toughness, high strength and high tempering resistance

Vacuum refining (Option of high pressure gas quenching or oil quenching)

Vacuum annealing

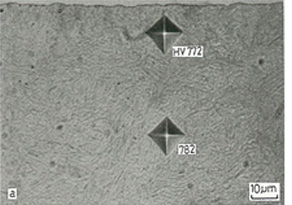

High concentration carburized structure High concentration carburizing: The structure of granular carbide (FeCr)3C of 1-2μm dispersed on the martensite base is high resistance to high temperature softenization. |

| Improvement of resistance to tempering softenization | |

|

|

| High temperature rapid carburizing: Possible to make a short time treatment for carburizing at 950-1000℃ | |

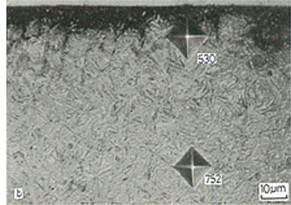

High concentration carburized structure Less internal oxidation: No imperfect quenching (internal oxidation) and external appearance of brilliant color owing to quenching under vacuum |

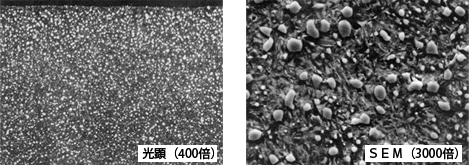

Optical microstructure of low pressure carburizing layer |

Optical microstructure of Rx gas carburizing layer |

| Microstructures of (a) INFRACARB and (b) Gascarburizing process. JIS SCM415, ECD=0.7mm | |

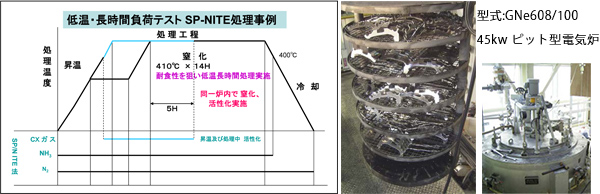

Gas Carburizing/Liquid Carburizing Process – SP-NITE

Process

Gas nitriding for high alloy steels such as austenite stainless steel, etc. and other materials being hard to treat with nitriding

Treatment obtaining both high hardness and superior ware resistance on stainless steel materials by a long-time and low temperature nitriding.

Low temperature nitriding aiming at holding the material strength.

Automatic operation of ammonium control by analyzing system.

Improvement of no oxidizing atmosphere in furnace or vacuum evacuation or nitrogen purging before treatment.

Cleaning of exhaust gas by gas resolving furnace

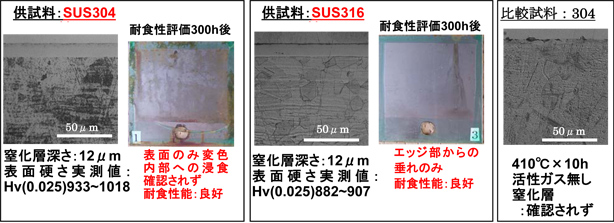

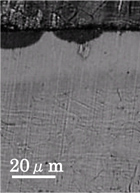

Comparison of cross sections structure between SP-NITE Treatment and conventional treatment

- Conventional treatment

SUS304

580℃x3h

Without active gas

Uneven nitrided layerSUH35

580℃x3h

Without active gas

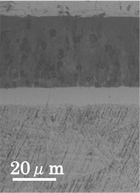

Uneven nitrided layer - SP-NITE treatment

SUS304

580℃x30min

Nitrided layer:Uniformity40μ

Hv(0.05)1340SUH35

580℃x30min

Nitrided layer:Uniformity27μ

Hv(0.1)1300

Activation of parts by hydro carbon gas (CX gas) in the same furnace

Automatic process control by inputting the treatment pattern

High strong, high wear resistant SP layer on SUS material

Activity of parts by hydro carbon gas (CX gas) in the same furnace

Automatic process control by input of treatment pattern

External appearance before and after low temperature nitriding treatment

-

SUS304 -

SUS316

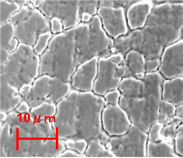

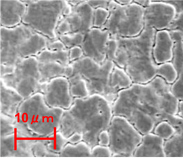

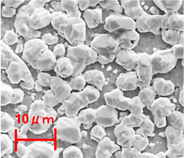

Surface observation before and after low temperature nitriding treatment, SEM

-

SUS304 Not treated -

SUS304 SP-NITE(430℃) -

SUS304 ISONITE TF(580℃)

Surface roughness before and after low temperature nitriding treatment

Performance test on sample treated with low temperature nitriding process

(surface hardness, cross section structure, wear resistance evaluation)