PARKERNETSUSHORI KOGYO

ご希望のお客様はこちらから▶

目的から事業内容を見る

What's New

新着情報

- 2023/10/13

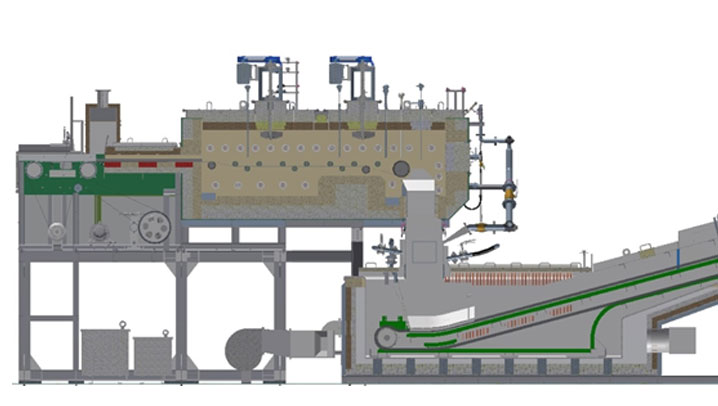

- 新製品「次世代型水添加式オーステンパ処理設備 WaAT」紹介頁開設

- 2023/10/13

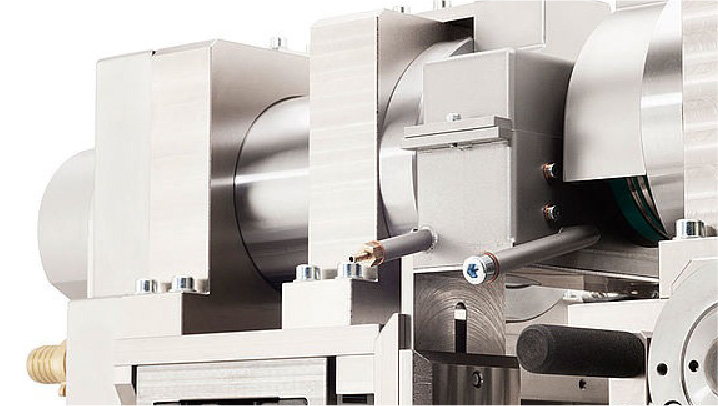

- 新製品「バッチタイプ低圧浸炭炉 ECOシリーズ」紹介頁開設

- 2023/08/04

- 熱処理セミナーのお知らせ

新製品のお知らせ

SERVICE

CORP INFO

「確かな技術力」でお客様のニーズを形にし

「ものづくり魂」でお客様の信頼に応えます

1956年(昭和31年)、当社は金属熱処理に用いる薬剤の輸入販売業務からスタートし、金属材料における表面改質のフロントローとして日本製品の技術発展に貢献。「熱処理設備の設計・製作」「熱処理関連薬剤の製造販売」「熱処理加工業者」の三位一体を強みに、金属熱処理の総合企業として展開してまいりました。ものづくりの現場で培ってきた「品質」「生産力」「開発力」をより高度な域へと昇華させるとともに、新たな海外市場、新たな加工技術、AIロボット等による新たな製造環境など、次世代領域をターゲットに展開しています。

PNK TOPICS

DOWNLOAD

弊社のカタログおよび各種データを

ダウンロードいただけます。

RECRUIT

パーカー熱処理工業では一緒に働く

人材を募集しております。